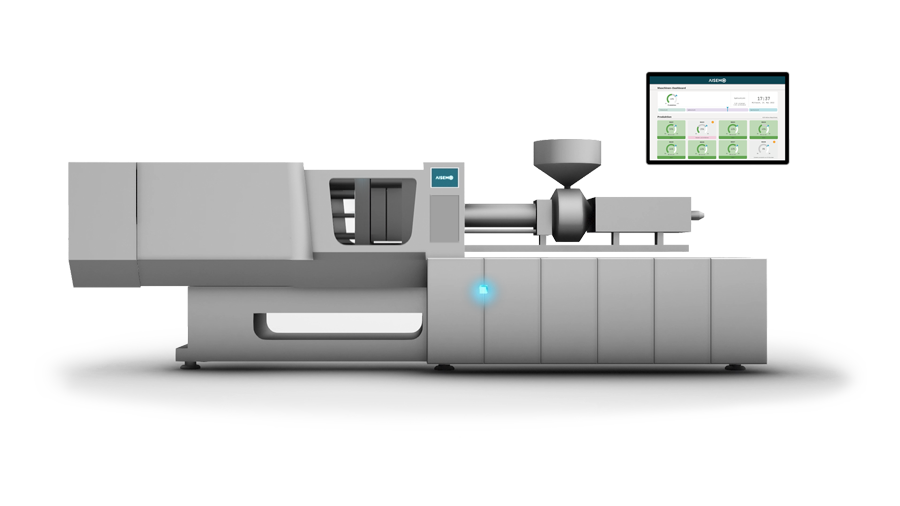

Perfect overview in the machine park

The extra AISEMO components offer your staff an optimum insight into the production status of the injection moulding machines.

- AISEMO Dashboard monitor for the real-time overview of availability and downtime causes of all machines

- AISEMO Tablet for direct downtime recording at the machine

- AISEMO ConnectBox for additional data recording at the machine

Keep track at any time and any place!

Downtime recording

The AISEMO Tablet allows staff to record downtimes directly at the machine.

Rapid response

The AISEMO Dashboard returns the production status of all injection moulding machines.

Digitalisation of machines

Recording of valuable machine data irrespective of manufacturer, type and age.

Support of production staff with accessories for the machine park

Dashboard monitor for the production workshop

Perfect presentation of real-time data from the machine park

- Status overview of machinery for rapid response times in the case of downtimes

- Prioritisation of staff assignments in the case of unscheduled downtimes due to the distinction of new and already classified downtimes

- AISEMO HDMI connection box for connecting large screens in the production workshop

Recording of production feedback in the tablet directly at the machine

The touch interface at the machine allows staff to record data directly at the machine - the place where the information is available

- No paperwork hassle to record production data and problems

- Pre-defined downtime causes for standard data recording

- Visibility of downtime causes in realtime

Perfect monitoring of machine availability

In addition to the AISEMO SensorTag, the AISEMO ConnectBox returns valuable data to determine the machine availability.

- Continuous monitoring of the cycle time and the cycle number in realtime

- Automatic availability and downtime recognition

- Data recording irrespective of machine manufacturer

More products

Potential calculator

How much potential is there in the reduction of downtimes in injection moulding?