Increased productivity & lower costs in injection moulding

A flexible and intelligent one-stop solution for networking the most varied injection moulding machines.

Most injection moulding machine parks never use their full production potential

Labour-intense data recording

Many enterprises record their production data using labour-intense and error-prone processes. A low level of digitalisation prevails, and island solutions result in complex data recording procedures. A holistic analysis of production data is not possible without a good data basis.

Complex scheduling tools

Manual scheduling tools involving a lot of paperwork do not take account of the ACTUAL production status.

Production delays are communicated too late. Time-intensive rescheduling needs to be done manually, and there are no automatic status updates.

No success monitoring

Measuring success is a key factor to increasing productivity and motivating employees. Missing reporting standards make it impossible to measure the efficiency of optimisation measures.

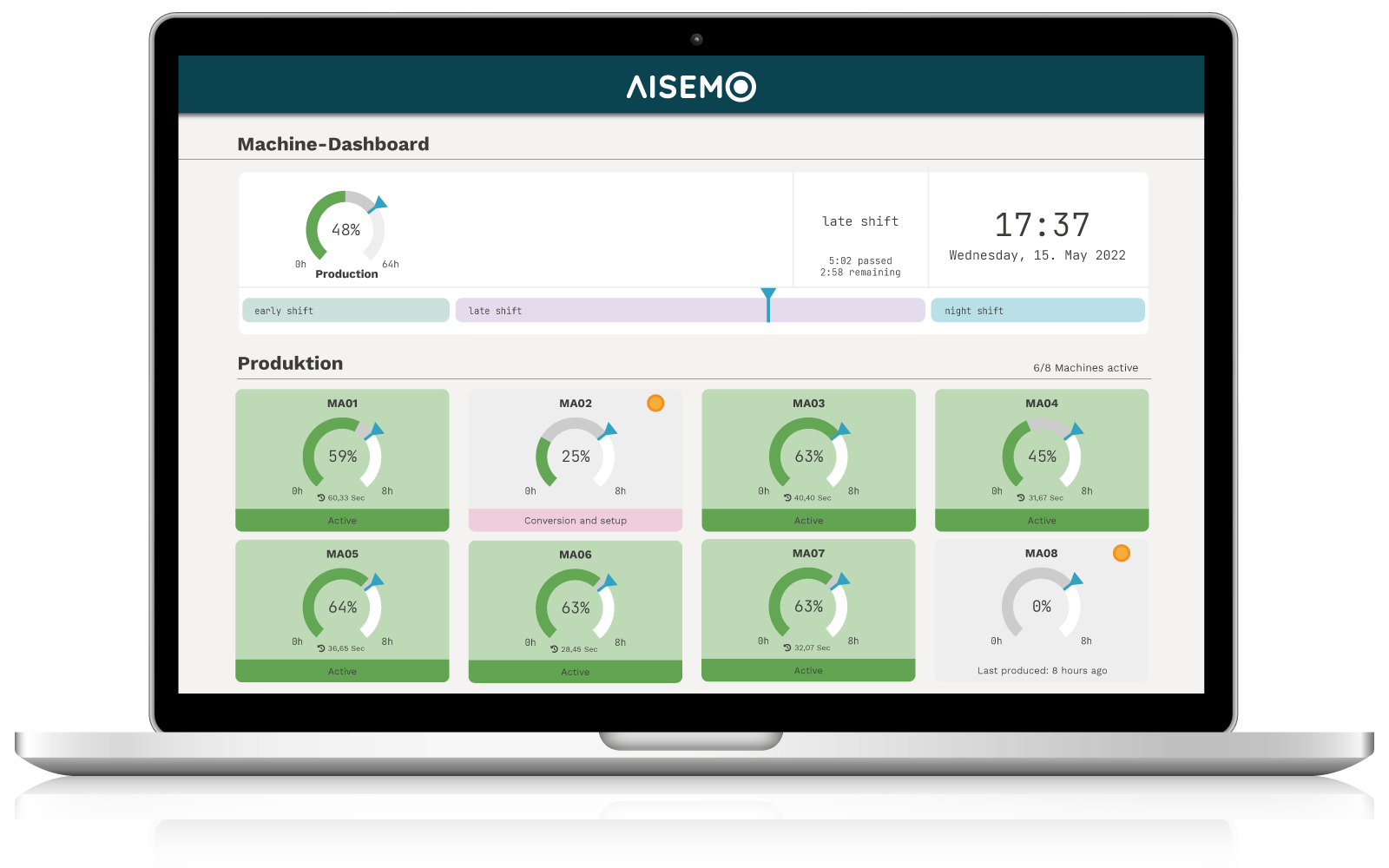

AISEMO Analytics provides a full overview of all injection moulding machines, production orders and sites

Real-time data from the machine park

- Status overview of machinery for rapid response times in the case of downtimes

- Prioritisation of staff assignments in the case of unscheduled downtimes

- Direct downtime recording at the production machine

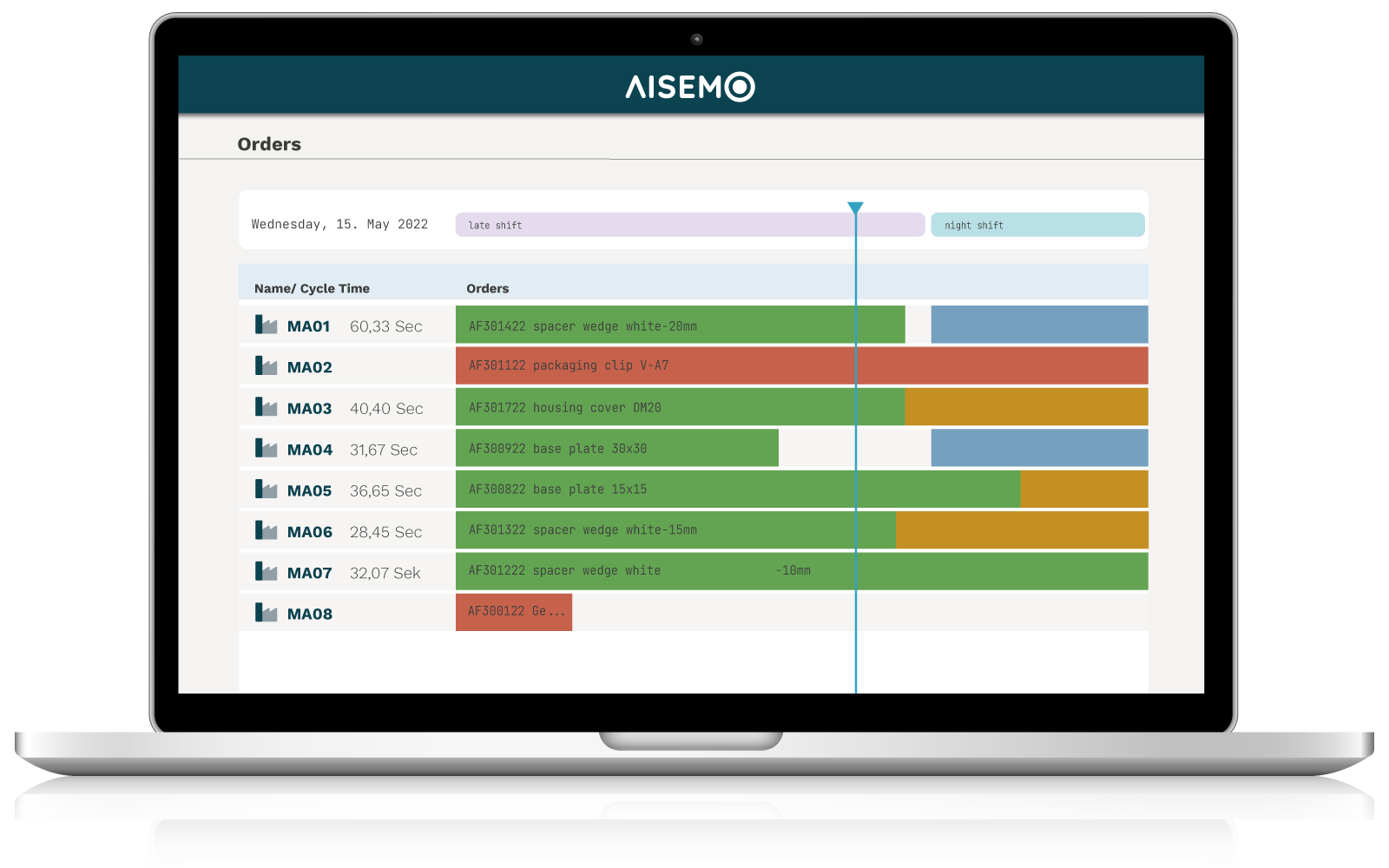

Integrated order scheduling

- Production delays are considered in order scheduling in real-time

- Automatic analysis of downtime causes and downtime duration by order

- Scheduling assistance and order documentation

Efficient production monitoring by means of OEE dashboard

- Identification of weak points in production processes

- Recognition of production potential regarding machines, tools or orders

- Improved status assessment and long-term success monitoring

Increase the productivity of your machine parks in 3 steps

Get to know AISEMO Analytics

Identify the system requirements and test our production functions. This is the only way you can select the right product.

Install the system

Install the hardware components in the production workshop within one day and establish the software accesses for your employees. You get immediate access to the production data.

Optimise production

Track and analyse your production data with AISEMO Analytics. Your employees may record problems by a standard procedure directly on the machine. This allows you to optimise production specifically.

“Our response time to downtimes could be reduced to a few minutes owing to AISEMO Analytics”

Plug-and-play: A flexible and intelligent solution for the injection moulding industry

Flexible networking

All types of injection moulding machines of any age, and irrespective of the manufacturer and location

Rapid setup

Independent system installation: No integration into local IT infrastructure and no interface adaptation required

Ready to use on the spot

Monitor and analyse production data in real time via Software-as-a-Service solution

Potential calculator

How much potential is there in the reduction of downtimes in injection moulding?